Zhou Hongchun, a researcher from the Development Research Center of the State Council, visited Baotai Group for research

Time:2021-03-17 10:06:14 Source:江西保太集团-亚娱体育·(中国)官方网站 View Rate:2593

Summary:On the afternoon of March 15th, Zhou Hongchun, a researcher from the Development Research Center of the State Council, visited Jiangxi Baotai Nonferrous Metals Group Co., Ltd. for an investigation and was warmly received by Peng Baotai, Chairman of Baotai Group.

On the afternoon of March 15th, Zhou Hongchun, a researcher from the Development Research Center of the State Council, visited Jiangxi Baotai Nonferrous Metals Group Co., Ltd. for an investigation and was warmly received by Peng Baotai, Chairman of Baotai Group.

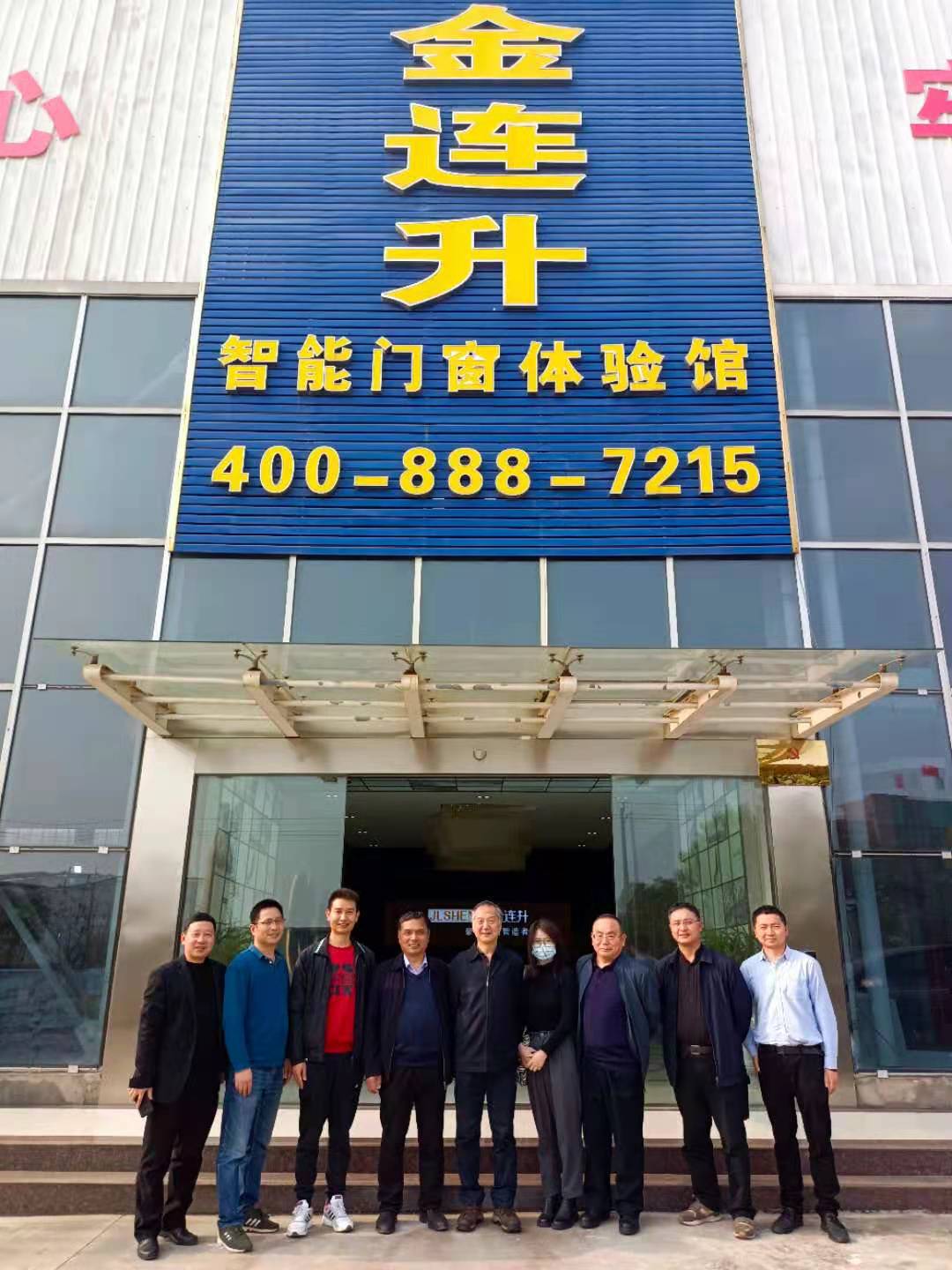

Accompanied by Chairman Peng, the research group visited the upper guide workshop, T2 copper bar workshop, aluminum ingot workshop and JinLianSheng intelligent doors and Windows exhibition hall. During the visit, we fully understood the development model of the whole circular industrial chain of Baotai Group, which includes recycling of recycled metals -- rough processing -- fine processing -- intelligent manufacturing.

At the symposium, researcher Zhou Hongchun expressed his confusion: there are many renewable resources recycling companies around, why only Baotai Group is crowded?

Chairman Peng explained: There are two main aspects.

1. "Baotai price". On the website of Baotai Group, nearly 60,000 visits are made by customers every day. The peak traffic is between 10 and 14 o 'clock, and the peak time is around 11 o 'clock. Botai Group's online quotation is also around 11 o 'clock. In the middle of the night there are many foreign people watching the " Baotai price". Our marketing strategy is "high quality and low price, open and transparent price."

2. High quality and low price products. The company introduces advanced production equipment at home and abroad, uses the industry's leading production technology, internal training of knowledge-based, technology-based management personnel, which Reduce the production cost. The company's R&D department research and develop, and has achieved excellent results, product quality was on a new level. The company adopts the way of cash transaction, attracting a large number of supply merchants and sales customers.

Researcher Zhou mentioned that the annual output value of Baotai Group is nearly 8 billion, most of which is concentrated in the processing of recycled copper and aluminum. Energy consumption is an important problem in production. Does the group have any good methods in reducing energy consumption?

Recycled copper is mainly processed by electric furnaces, while recycled aluminium is processed by natural gas, said Peng Dong. As early as 2017, the company fully completed the "coal to gas", using new energy to replace non-renewable coal, to achieve green development. Now, the second phase of solar photovoltaic power generation has been built on the roof of the workshop, with an annual output of more than 5 million kWh. All the power generation is for self-use. The third phase of the 5-megawatt solar photovoltaic power generation will be completed and put into use next year.In the future, the fourth and fifth phases of solar photovoltaic power generation will be built to achieve the goals of energy saving and emission reduction, "carbon peak, carbon neutral".

Researcher Zhou mentioned: the development of Baotai Group is booming, the demand for raw materials is also increasing day by day, whether the supply of raw materials in China is sufficient?

Peng Baotai replied: Baotai Group's current raw materials mainly rely on domestic. In order to cope with the shortage of raw materials in the domestic market, the Group began to expand the overseas market in 2020. Now it has been applying for the qualification of domestic consignee, importing recycled copper and recycled aluminum through the rail-sea combined freight train in the Yingtan International Port Economic Zone, expanding the source channels of recycled metals to meet the raw material demand for industrial development. Through the adjustment of advanced equipment and process, the "reduction, resource and harmless" treatment of recycled metals can be carried out, and the recycling of renewable resources can be turned into treasure thoroughly. At present, the annual production of 300000 tons of aluminum alloy ingot production line, 150000 tons of copper production line, polyaluminum chloride production line under construction, these production lines are expected to be put into production in three years, then the company's total output value will reach 20 billion.

Service Hotline:0701-5382189

Service Hotline:0701-5382189

Jiangxi Public Network Security No.36062202000027

Jiangxi Public Network Security No.36062202000027